When I’m faced with any British bike rebuild, I pitch in with complete confidence. Old bikes have been my hobby and livelihood since my teens and over that time I have built up a wealth of useful parts, nuts, bolts, tools, equipment, manuals and experience.

That’s fine for me, but realistically few enthusiasts have the luxury of such resources and I think that restoring the Project Honda 400 Four was quite a good reality check that reminded me how much more difficult – and expensive – restorations become when you are under-equipped.

Now that the job’s done, I’ve been thinking about what I found most difficult. There were odd things, like the fact that I barely used the lathe that usually forms the backbone of my rebuilds, or that my very basic, bootfair selection of metric spanners, sockets and Allen keys proved surprisingly adequate.

I didn’t like being without thread repair equipment. It’s always a nuisance having to pull a job apart again to fix a stripped thread, but at least with your own kit it’s soon sorted. Being forced to rely on third parties, with services available only during working hours, made me very cautious with the spanners.

But strangely, I think my tiny selection of new metric fasteners was the biggest problem – fruitlessly sifting through the tin, trying to find one that wasn’t just a fraction too short, drove me to distraction. Funny that, although you might equip your workshop with all sorts of fancy tools and machinery, ultimately it’s really the simple, most basic of consumables that keep the job going.

TOP TIP: BLESSED RELIEF

Low oil pressure on 350/500 Triumphs means big trouble ahead. To keep an eye on it, I always fit the unpopular indicator type relief valve, which has a button that pokes out reassuringly. Why unpopular? Because they’re leak prone; a rubber pipe fits over the plunger like a fork gaiter, but the combination of flex and hot oil soon perishes it so that oil dribbles out of the button.

Better than a seized engine in my book, but many people prefer to fit the sealed-dome type. However, nowadays SRM Engineering manufacture a leak-proof and improved valve in shiny stainless for £50 plus VAT. Sorted

CRUISE CONTROL

Ken Adams is pleased with the starting and running of his 1970 Bonneville since fitting a pair of new Amal Concentric carbs, but asks if there’s anything he can do to make the bike tick over from cold. At the moment, unless he keeps the throttle slightly open it cuts out until warm, even the choke makes no difference.

He says: “I know I could adjust-up the friction screw on the twistgrip so that the throttle stays where I leave it, but it seems a bit dangerous – I like my throttles to shut when I let go!” The chokes on most British carbs are just slides that block off the air supply.

Since the pilot (tickover) range has its own air supply regulated by the air screw, this blockage doesn’t have much effect unless the throttles are actually open. More modern carbs – and Amal MkII Concentrics – use an enrichment device, an extra fuel jet covered for normal running by a rubberfaced plunger.

There’s usually also some kind of cam that partly lifts the throttle at the same time to create the fast tickover Ken’s looking for. Well, it’s not an available option with Ken’s carbs, but I think he should think again about the twist-grip friction screw. It’s a small cheesehead screw with a locknut that operates a spring steel ‘brake’ on the twist-grip drum; it can be set so that the throttle will stay put like a sort of cruise control.

I wouldn’t be without one; they’re useful for hand signals, but I agree you may not want it all the time. Pre-unit Triumphs had a handy knurled knob for instant adjustment, and on my bikes I back the lock nut hard against the screw head (the screw tip is peened over so it can’t fall out) providing a toggle that’s similarly operable with a gloved hand. If he does likewise, Ken will be able to nip the screw for warm-up and easily release it again for riding.

OUT OF LINE

Colin Gyue is rebuilding his 1961 BSA B40. It’s the type with a plain bush right-hand main bearing through which the big-end oil supply flows. The bush runs on a sleeve pressed onto the crank and Colin noticed that the oil hole on the sleeve isn’t completely aligned with the drilling in the crank.

“Could this restrict flow?” he asks. “I know these bikes have a reputation for bigend problems, but I’d like to minimise the risk!” Well it doesn’t sound ideal, Colin, but I’m sure there is a groove around the inside of the sleeve that allows oil to track round and into the crank whether or not the holes are aligned.

If I’m right and you don’t have the facilities to remove the sleeve, spray WD40 or similar (using the little pipe supplied) into the groove to make sure it’s clear. If the engine has had a blow-up in the past, there could be debris lurking and this close to the big end is about the most dangerous place to store it.

Oil feed via the timing-side bush was a popular system for many years. The problem is that wear in the bush makes it easier for oil to escape than to follow through the crank to the big end. Plain big end bearings need more oil than roller big ends and, to make it worse, being a tight fit on the crank they form a greater restriction to oil flow than rollers, so flow problems are increased. Clean oil is the answer to keeping the main bearing sound, so frequent oil changes should prevent trouble.

A DIFFERENT SLANT

Bo Stubkier got in touch from Denmark to correct me on my assertion (Fixes, January 2015) that Norton Commando engines can only be fitted vertically in Featherbed frames – and sent in the pic above of his own bike as proof.

He had to move the engine ¼in to the right and flatten the lower right frame tube slightly, as well as redesigning the centre stand and head steady, but it was nothing too complicated he reckons. Bo is now in the process of fitting an Alton electric starter and has promised to keep me posted on how that works out.

OUTDOOR BATHTUB

Paul Brown emails to ask if he could turn the ‘bathtub’ Triumph 3TA basket case he’s owned for the last 35 years into a useable green lane bike. He’s concerned whether fitting bigger wheel rims would offer enough extra ground clearance without modifying the frame. I think so; the 3TA was fitted with 17in wheels originally and I had a 5TA on the road with 19in wheels which was quite tall. A 21in front wheel would make more difference and could be balanced at the rear by slightly longer shock absorbers.

My concerns would be with the forks which are a bit feeble for off-roading; something from a more modern bike would do a better job. And the 3TA/5TA/ T100A tanks are structural; the mounting brackets are stout steel plates that run the length of the tank either side of the tunnel. If you replace the standard tank with another type, you lose the bracing and the handling suffers. Faced with vibration-related tank fractures, around 1964 Triumph moved to a rubbermounted tank – but to maintain the bracing effect, they had to fit a tube beneath the tank that bolted to the frame’s original tank lugs.

Soon after, the frame design changed to a more conventional type with a diagonal top tube, but on the early frames it’s definitely worth making up some sort of brace before fitting a non-standard tank. But otherwise, these 350/500 models are compact and fairly light making them popular off roaders.

DECAL DECLARATION

We got our wires crossed in the final part of our Honda 400 Four restoration (February issue). We wrongly credited the custom-made decals to KAS Racepaint when they were, in fact, the handiwork of the ever helpful Dean Hackett of CMD. If you fancy some decals for your project, contact Dean on 07873 377435 or drop him an email to: c_m_d@hotmail. co.uk. Top man, top decals and top service.

HOW TO: FIT THE ROCKER BOXES TO TRIUMPH TWINS

IT CAN BE FRUSTRATING – WITH NO SPACE FOR FINGERS, IT’S NOT EASY TO MATE THE ROCKERS TO THE PUSHROD TOPS. HERE’S THE KNACK...

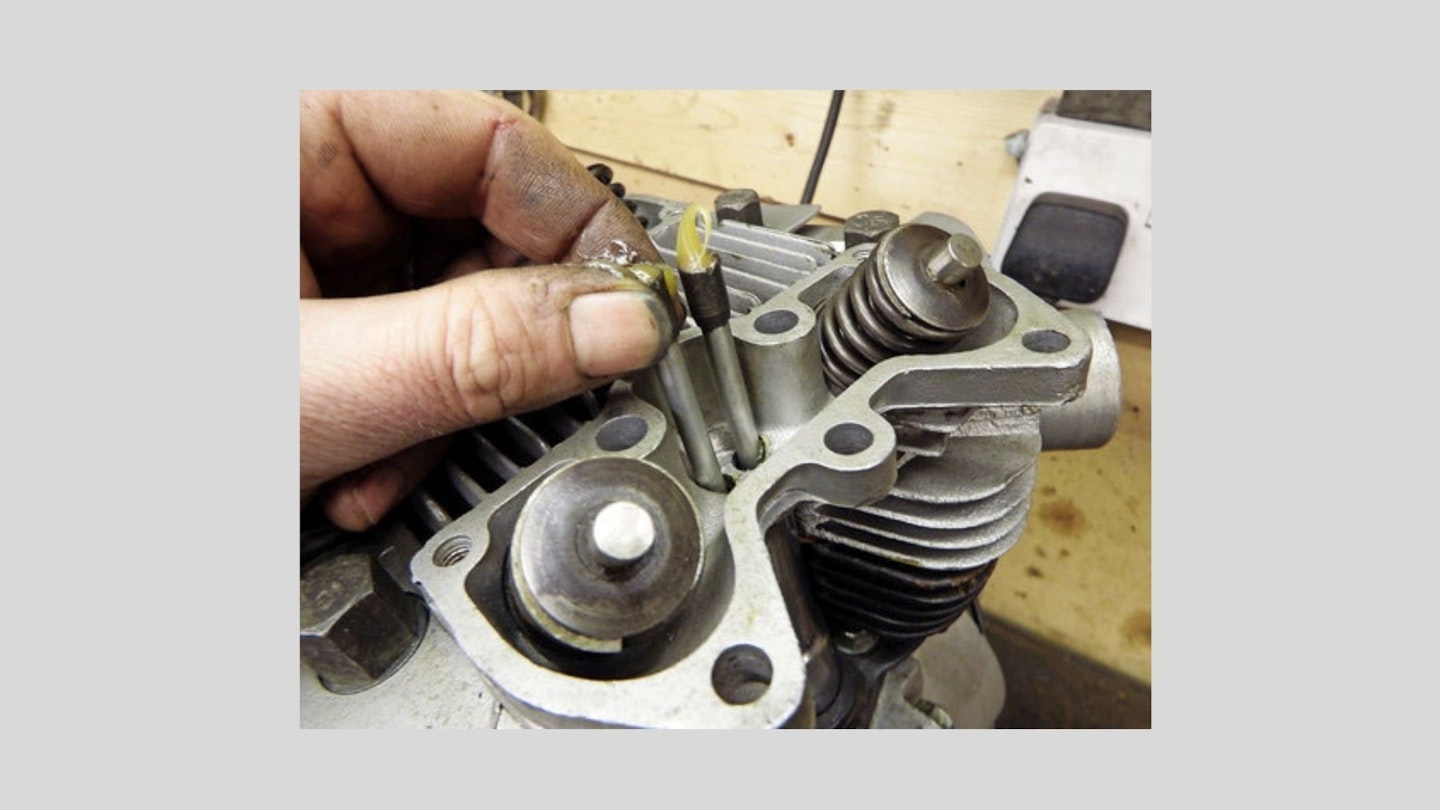

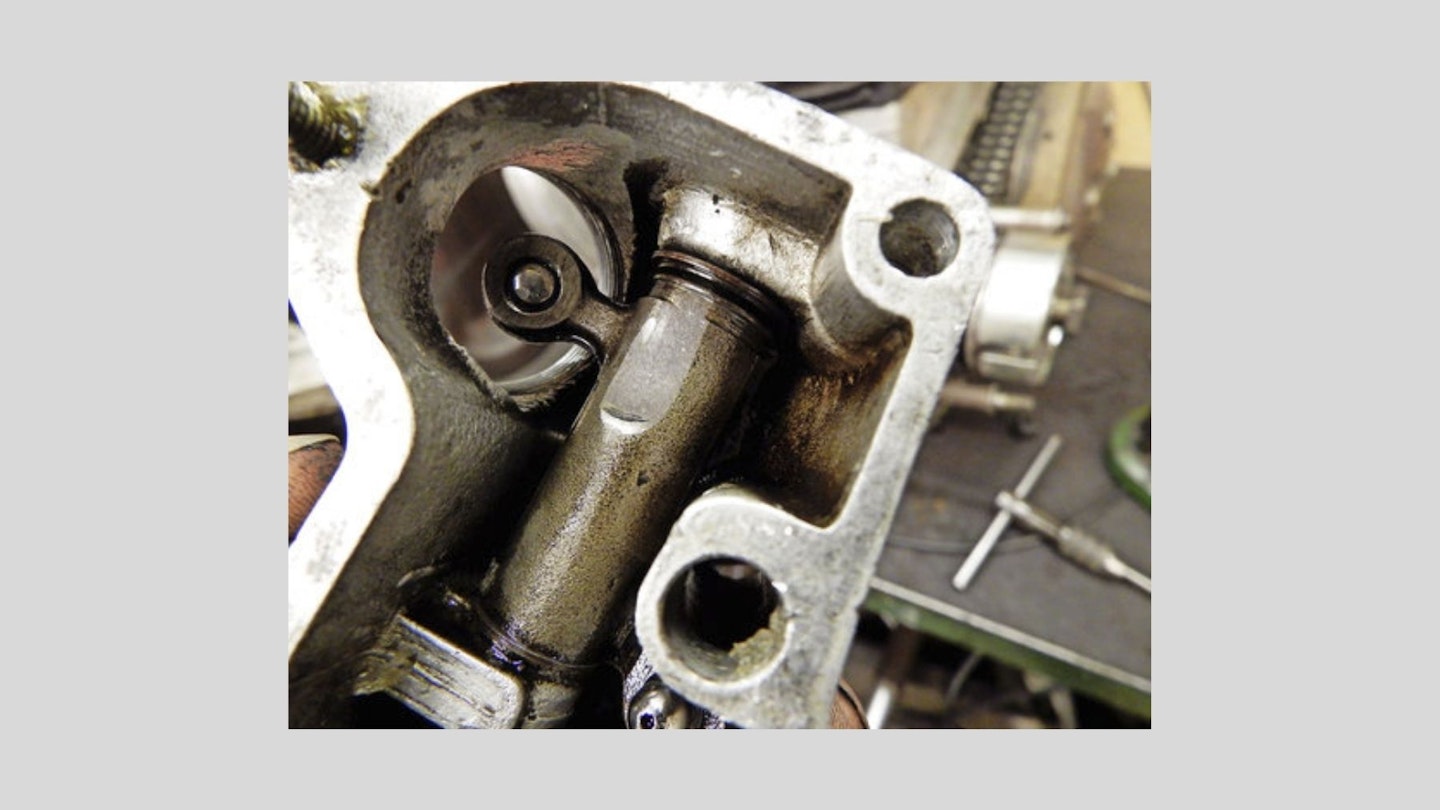

- This is a 1960 500cc head, but the principle’s the same for all Triumph twins. Locate pushrods in tappets with a blob of grease to prevent dislodging. Turn the engine till both are level.

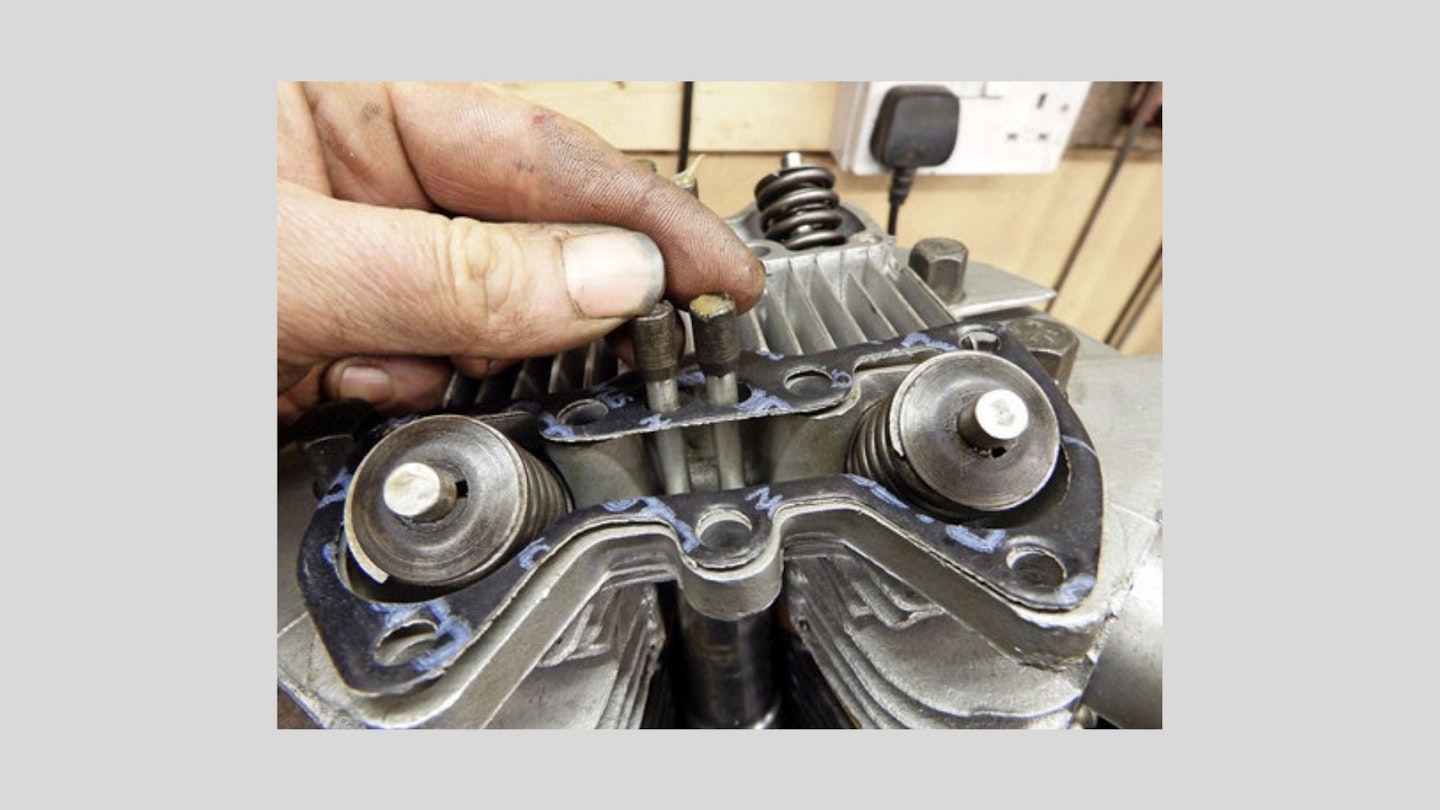

- Guide holes in the gasket line the rods up to the rockers. Without these guides the job is much harder, so it’s best to avoid using sealant instead of gaskets.

- Also, the rocker is relieved, in order to avoid touching the valve collar. Abandoning gaskets can cause it to contact; wire reinforced type gaskets are best.

- Supporting the rockers gently with your thumbs, lower the rocker box down vertically, feeling the pushrods engage as it settles down onto the gasket.